Project details

Title: Propylene (C3H6) production via oxidative dehydrogenation of propane (C3H8) with carbon dioxide (CO2)

Principal Investigator (Name/Surname): Paraskevi Panagiotopoulou

Host Institution: Technical University of Crete, School of Chemical and Environmental Engineering, www.tuc.gr, www.chenveng.tuc.gr

Projects’ Duration: 36 months

Total Budget: 195.000,00 €

Financed by: Hellenic Foundation for Research & Innovation (H.F.R.I.) under the “2nd Call for H.F.R.I. Research Projects to support Faculty Members & Researchers” (Project Number: 3367), www.elidek.gr

Cooperating Organization: University of Patras, Department of Chemical Engineering www.upatras.gr

Project Objectives

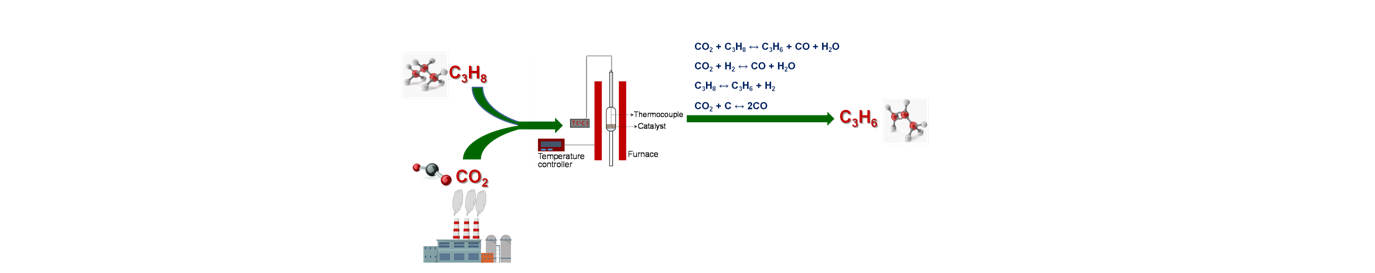

Propylene is a versatile precursor for the formation of various derivatives (e.g. polypropylene, acrylic acid, acrylonitrile, cumene etc.) used in our daily life and thus, it is considered as a key component of the chemical industry. One of the traditional methods used for propylene production is the reaction of propane dehydrogenation, which is strongly endothermic and equilibrium limited. The reaction requires high temperatures, suffering from fast catalyst deactivation as well as low C3H8 conversions and C3H6 selectivities. Oxidative dehydrogenation of propane in the presence of molecular oxygen has been proposed as an alternative pathway, which is an exothermic reaction, with no thermodynamic limitations, and operable at low temperatures. The main drawback of the process is the deep oxidation of both C3H8 and C3H6 toward carbon monoxide (CO) and CO2, resulting in low propylene yields. Thus, replacing of molecular oxygen by a milder oxidant, such as CO2, has recently gained interest as an alternative approach for selective propylene production.

The proposed project deals with the development and optimization of catalytic materials and the identification of optimal operating conditions for the production of propylene (C3H6) via oxidative dehydrogenation of propane (ODP), by using carbon dioxide (CO2) as oxidant. The main goal is to develop an alternative efficient process for simultaneous propylene production from propane (C3H8) and CO2 utilization. ODP with CO2 will not only meet the expected future high demand for propylene, but it will also contribute to elimination of CO2 in the atmosphere and therefore, climate changes.

The primary objective of the proposed project is to develop an innovative process for the production of propylene via ODP with CO2. One of the main roles of CO2 in the proposed process is the consumption of hydrogen (Η2) produced during the thermodynamically limited propane dehydrogenation (DHP) reaction. Thus, coupling of DHP with the Reverse Water-Gas Shift (RWGS) reaction is expected to enhance propylene yields and therefore, will be investigated in detail. Synthesis, characterization and optimization of catalytic materials for the oxidative dehydrogenation of propane, characterized by high activity and selectivity toward propylene, low selectivity toward ethylene and methane, enhanced stability with time on stream and tolerance to coke formation will be a major part of the project. Emphasis will be given in the development of materials able to favor coke gasification via the reverse Boudouard reaction, thus ensuring catalyst stability. The identification of physicochemical parameters which determine catalytic activity, as well as the investigation of reaction kinetics and mechanism with the use of in situ FT-IR and transient mass spectrometry (transient-MS) techniques will be studied. Optimized catalysts will be incorporated into appropriate reactor configurations and tested under realistic reaction conditions. The optimized catalyst/reactor system will be able to convert efficiently propane into propylene, which may then be used in a number of applications.